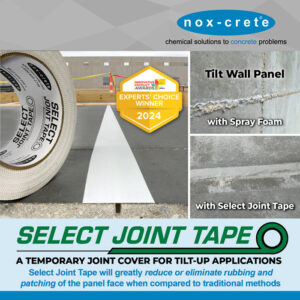

Nox-Crete's Select Joint Tape has been recognized as a 2024 Experts' Choice Innovative Product Awards Winner by World of Concrete, a testament to the company's commitment to innovation in the concrete construction industry. This accolade highlights the product's sustainable innovation, which improves existing processes and offers contractors and producers enhanced productivity, safety, and engineering efficiency. As a leader in Concrete Release Agents, Tilt-Up Cure & Bondbreakers, Concrete Chemicals, and Tilt-Up Accessories, Nox-Crete's Select Joint Tape is a result of the company's dedication to providing solutions that meet the evolving needs of the industry.

The Innovative Product Awards, powered by World of Concrete, is an annual recognition program celebrating advancements in concrete equipment, materials, services, and tools across eight categories. The winners, including Nox-Crete's Select Joint Tape, were chosen by a panel of industry experts and World of Concrete editors for their ability to set new industry standards and enhance performance and competence in the field.

Nox-Crete has a rich history of developing high-quality chemical solutions that enhance the durability, aesthetics, and performance of concrete structures. The company serves a diverse range of professionals in Tilt-Up, Forming, Decorative Concrete, Precast, and Concrete Flooring, offering tailored solutions to ensure the best outcomes for specific projects.

As a leading innovator in the concrete construction industry, Nox-Crete is dedicated to advancing the industry through quality and innovation, helping contractors achieve superior results on every project.

View the PDF for our IPA Awards Press Release.

Select Joint Tape has excellent adherence to properly prepared green concrete and leaves no residue on the casting slab when removed. Select Joint Tape may be applied before or after applying Nox-Crete’s Silcoseal water-based bondbreakers.

Key Advantages Compared to Traditional Methods:

• Forms a tight seal to prevent concrete, dust

and debris from entering a saw-cut joint

• Compatible with Silcoseal Select and 2000F Bondbreakers

• Leaves no adhesive residue on the casting slab

• UV Resistant for up to 28 days

• Serrated edges

• Waterproof

Select Joint Tape is sold by the case with 24 rolls/case. If you’re interested in Select Joint Tape, Click HERE for more information.

chemical solutions to concrete problems

chemical solutions to concrete problems

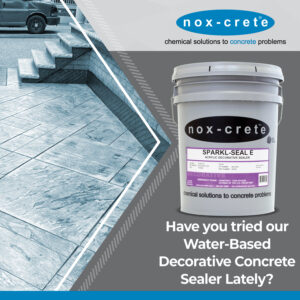

One of the primary advantages of water-based, high-gloss decorative acrylic concrete sealers lies in their ability to create a captivating wet-look finish. This wet-look effect adds a sense of depth and dimension to the concrete surface, enhancing its color, visual appeal and providing a luxurious shine that mimics the traditional solvent-based acrylic sealer appearance while being eco-friendly. Whether it's a commercial space looking to make a lasting impression on customers or a residential property aiming to revitalize living areas with concrete floors, the beauty of a water-based concrete sealer is that it can also be used in interior spaces. The wet-look finish achieved with these sealers brings an undeniable charm that transforms ordinary concrete into a stunning focal point.

One of the primary advantages of water-based, high-gloss decorative acrylic concrete sealers lies in their ability to create a captivating wet-look finish. This wet-look effect adds a sense of depth and dimension to the concrete surface, enhancing its color, visual appeal and providing a luxurious shine that mimics the traditional solvent-based acrylic sealer appearance while being eco-friendly. Whether it's a commercial space looking to make a lasting impression on customers or a residential property aiming to revitalize living areas with concrete floors, the beauty of a water-based concrete sealer is that it can also be used in interior spaces. The wet-look finish achieved with these sealers brings an undeniable charm that transforms ordinary concrete into a stunning focal point.

4. How did our product help make your project successful?

4. How did our product help make your project successful?

Reese was approached by a customer who topped a partial aggregate, broom-finished sidewalk at a residence with an acid stain. Upon completion, the stain turned a displeasing shade of orange. Reese was dispatched to fix the color issues.

Reese was approached by a customer who topped a partial aggregate, broom-finished sidewalk at a residence with an acid stain. Upon completion, the stain turned a displeasing shade of orange. Reese was dispatched to fix the color issues.